- Corporate

- Products

- R&D Center

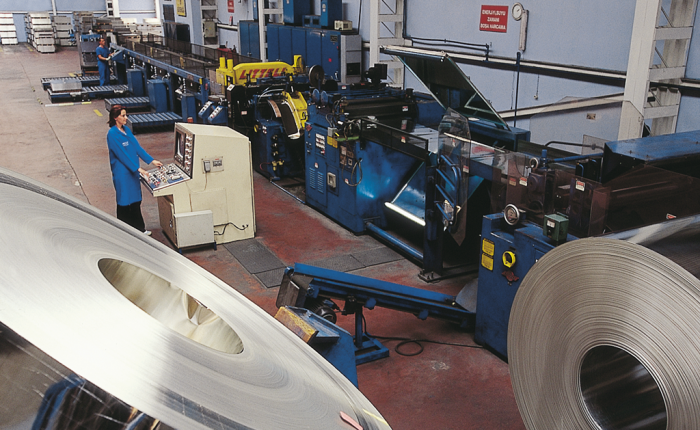

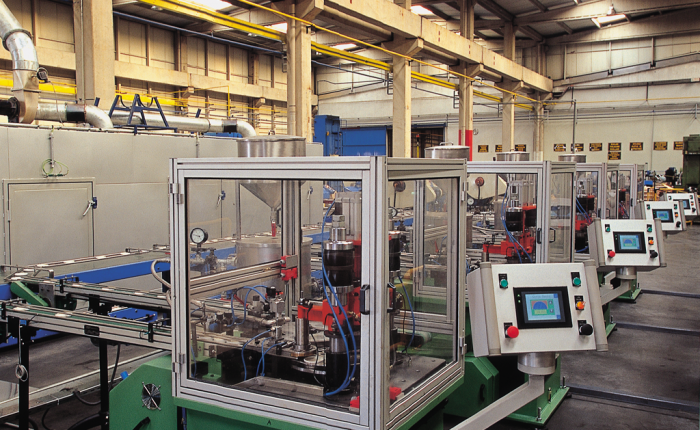

- Our Plants

- HR

- Sustainability

- Media Kit

- Contact

- Company Profile

- Investor Relations

- Mission & Vision

- Our Core Values

- Sarten Innovation

- Our Policies

- Our Certifications

- Social Responsibility

- Work Ethics Rules

- Sponsorships